Title:IppinNet of Tougei System (IoT Ceramic System)

Displayed Name:Team IoT

| Concept / Overview |

|---|

| We made an "Ippin camera" using GR-CITRUS + WA-MIKAN + camera module. Background: When people make something using a Gadget Renesas board, they most likely create just one item. There is no concept to make many of the same. However, "making a large number of things" becomes very important in the end. Here, we proposed a system to reproduce lots of the same thing. Goal & Concept Make lots of the same thing! Implementation method We devised a system that can make a lot of the same thing using the GR board. |

Idea

When making something, we most likely create just one thing. There is no concept to make a lot at one time. However, in the end, making a lot is the key to success.

- Idea details

A mold to reproduce many of the same item -- a soy sauce plate

- What does the soy sauce plate look like?

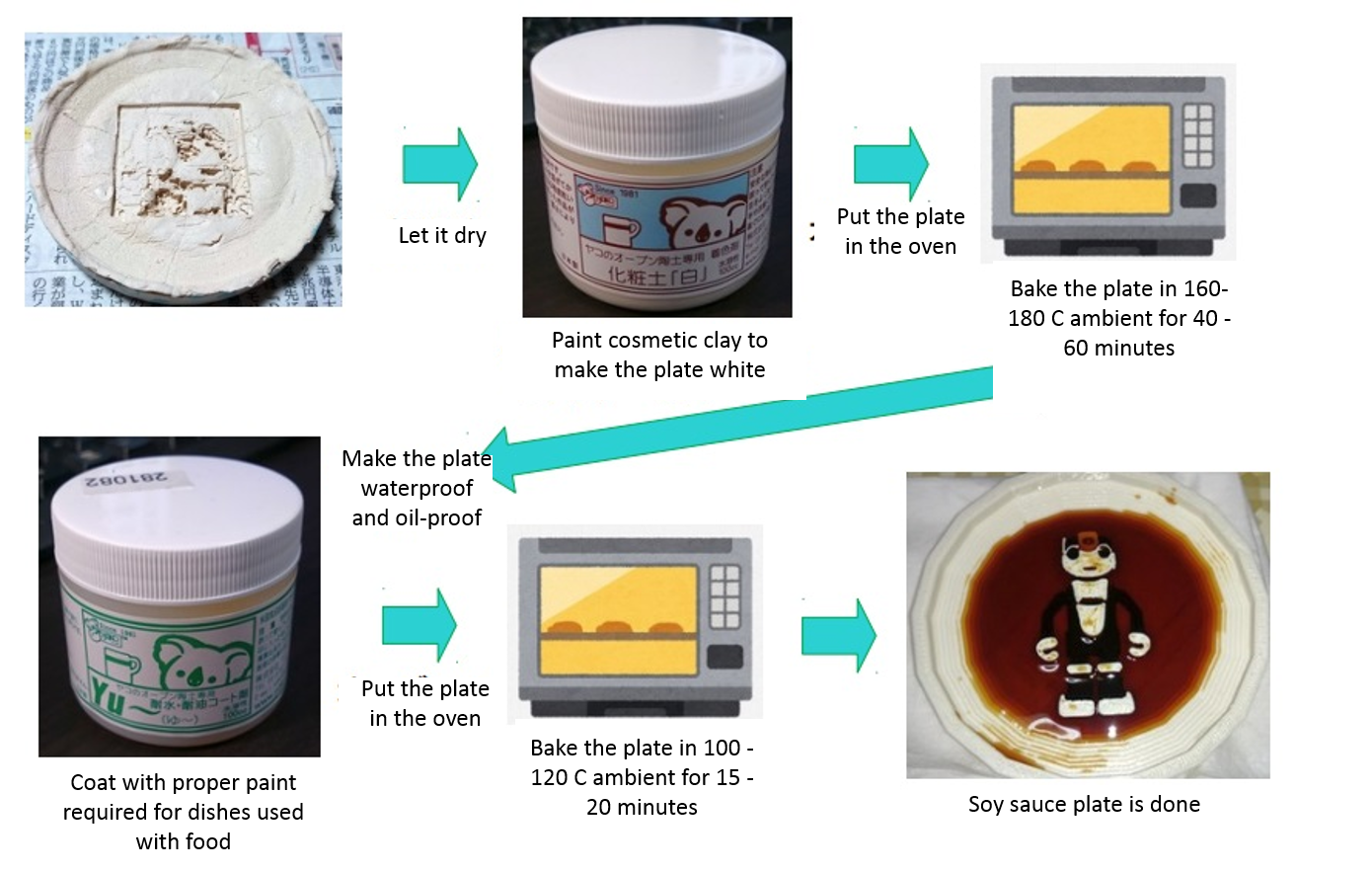

When soy sauce is poured into the plate, a picture emerges.

- How to make it?

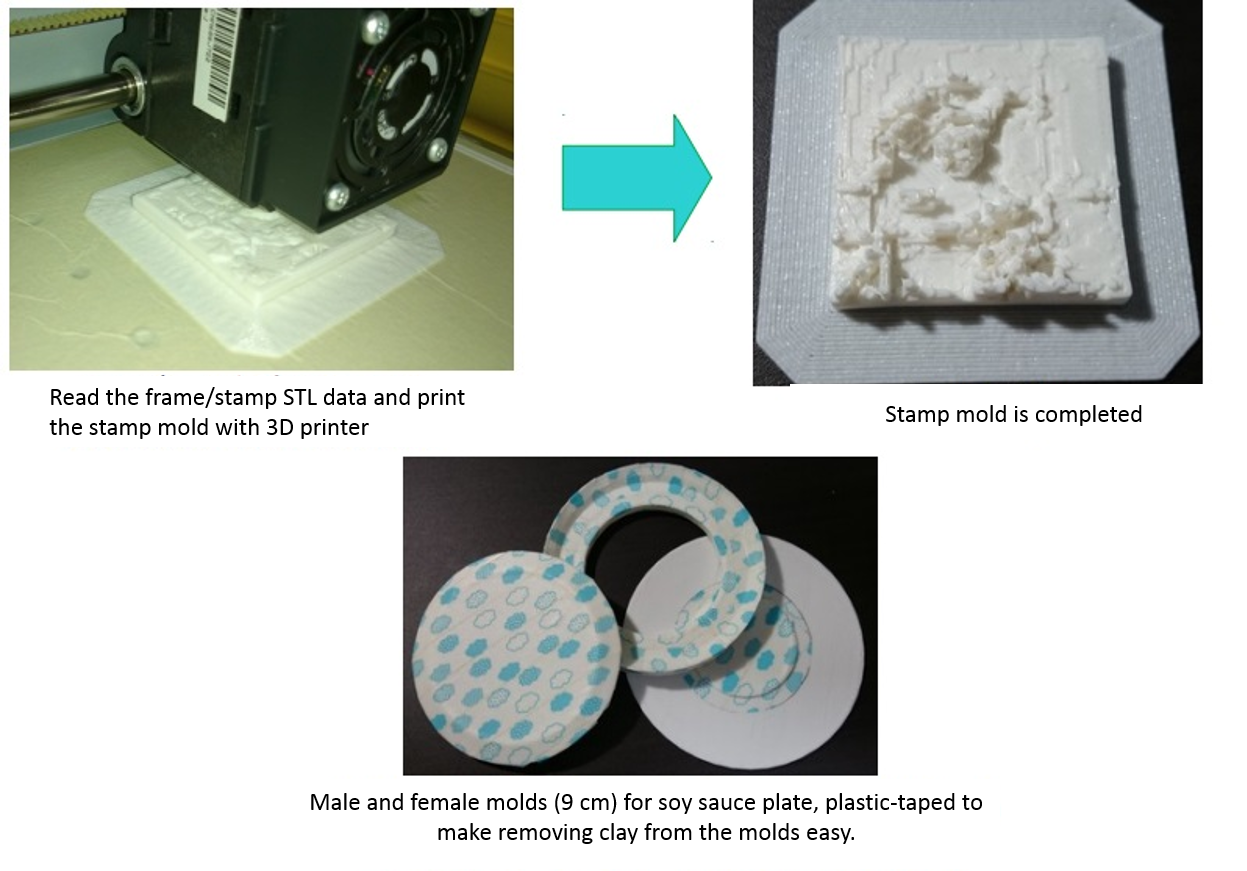

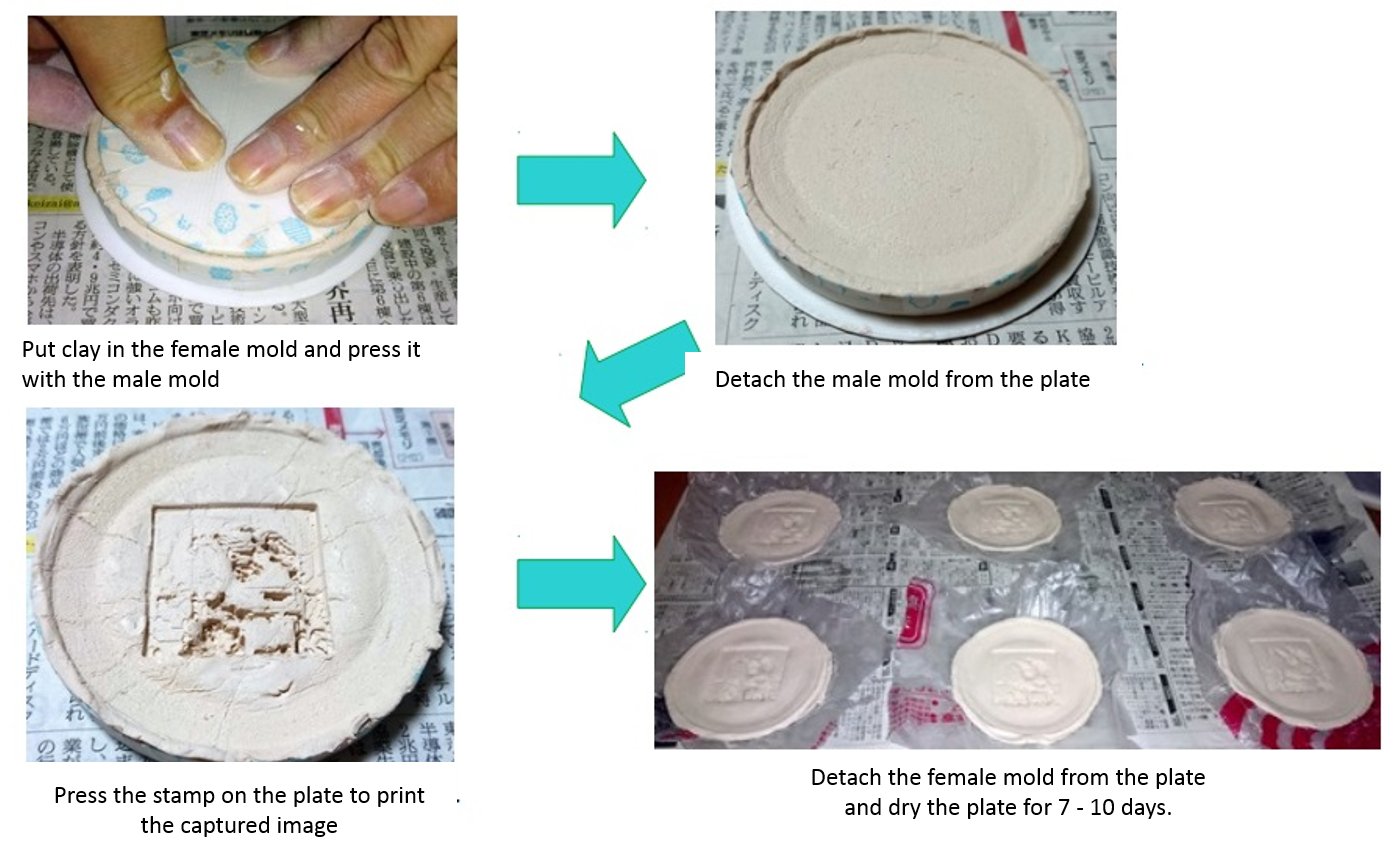

Make a mold with a 3D printer, die-cut the clay using that mold, burn it and produce many plates with it.

- How to make it?

Use a 3D printer to make the mold. Form the clay using the mold. Fire the molded clay plates in an oven, producing many soy sauce dishes.

- How to make the mold data?

Output STL file with GR-board.

- Which picture are used for the floating picture?

Pictures taken with the GR board.

- How do you make a picture float in the plate?

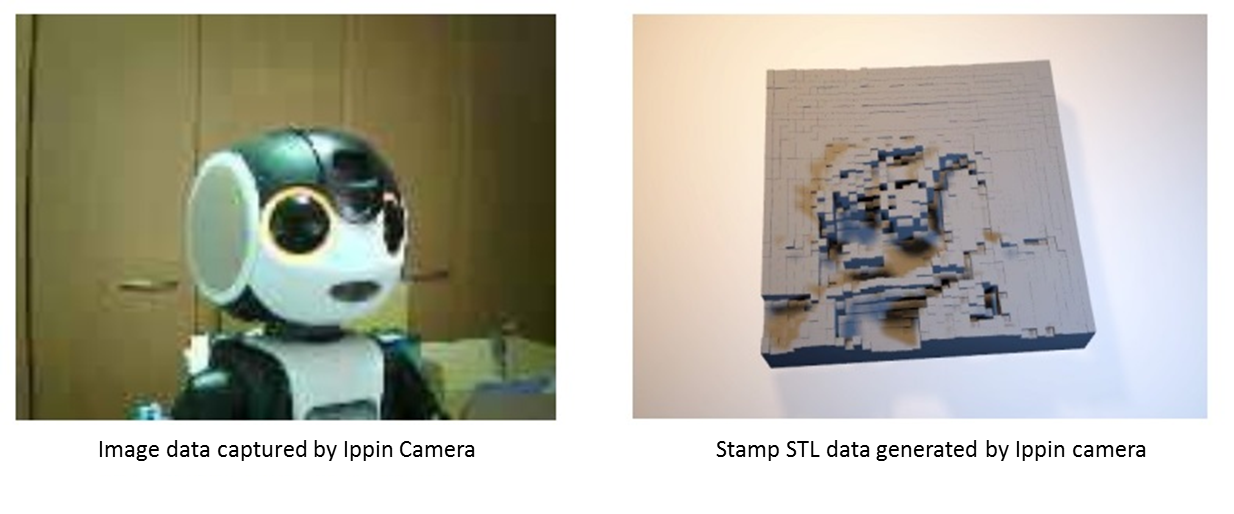

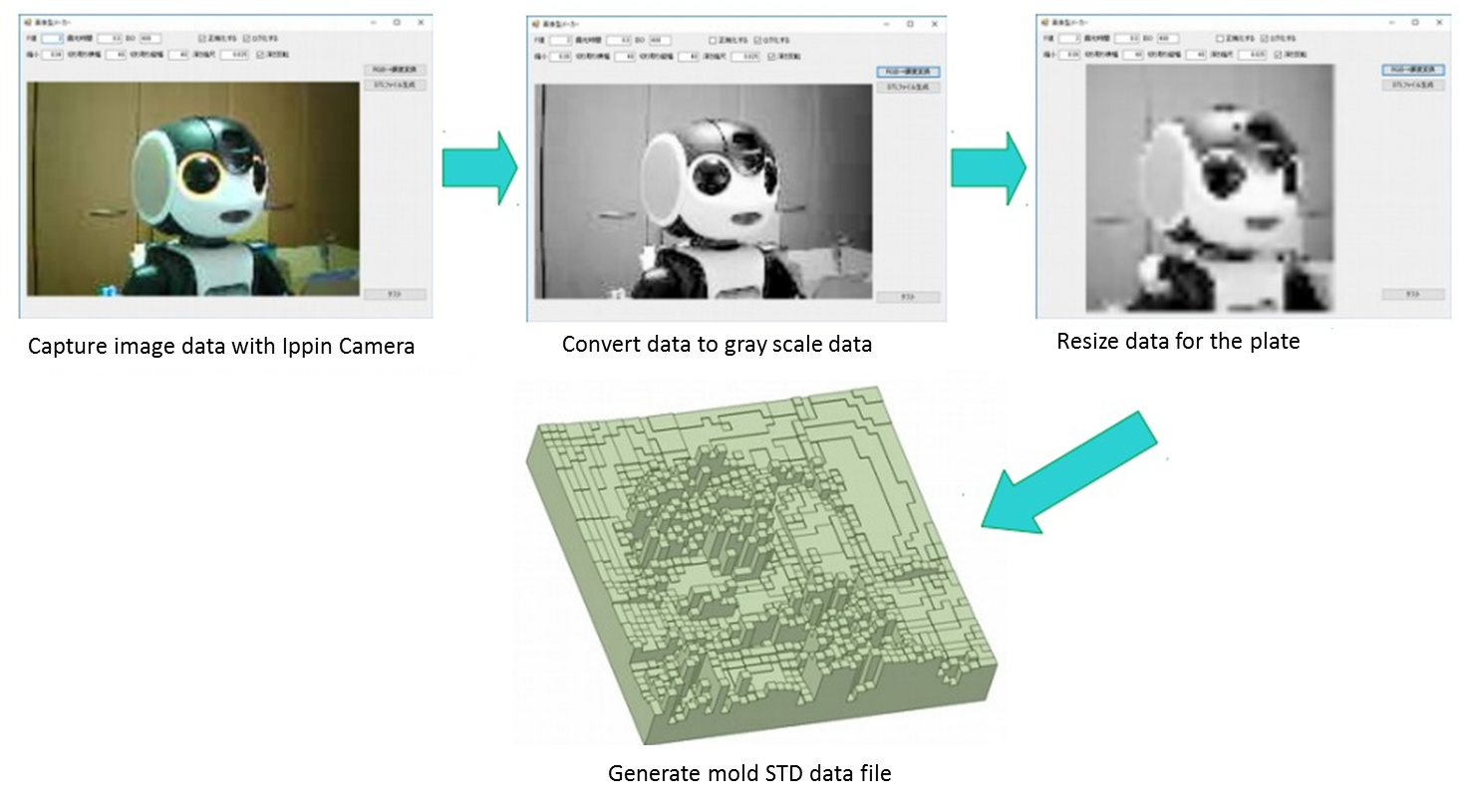

Convert the photo image to a gray scale image. Then, the dark and thin parts of the image turn to the deep and shallow STL data, respectively, generated in the board.

- How do you output STL data?

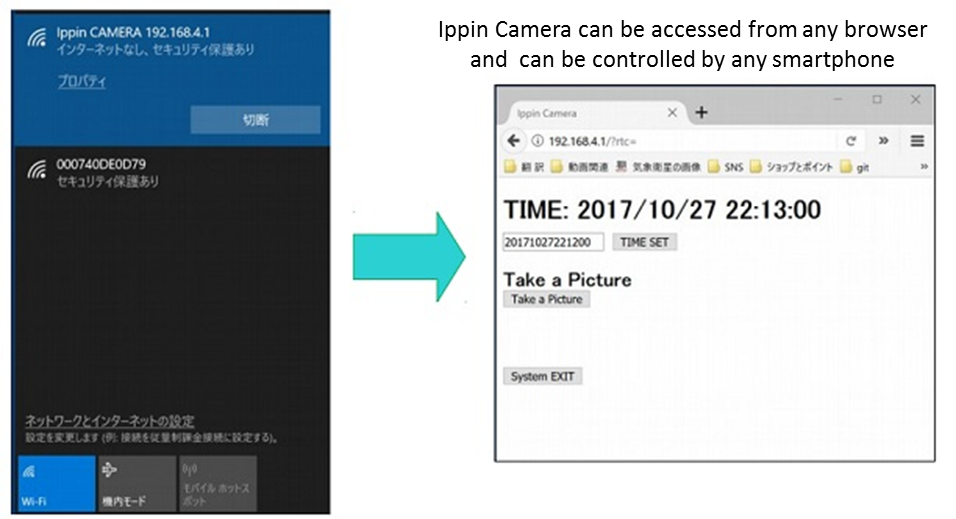

Build an http server in the connected WiFi board. The STL data in the server can be downloaded via the net.

* "Ippin" means a special creation, so we call this "Ippin Net," because the STL data is downloadable via the net, rather like downloading one special dish!

Demo video

Explanation

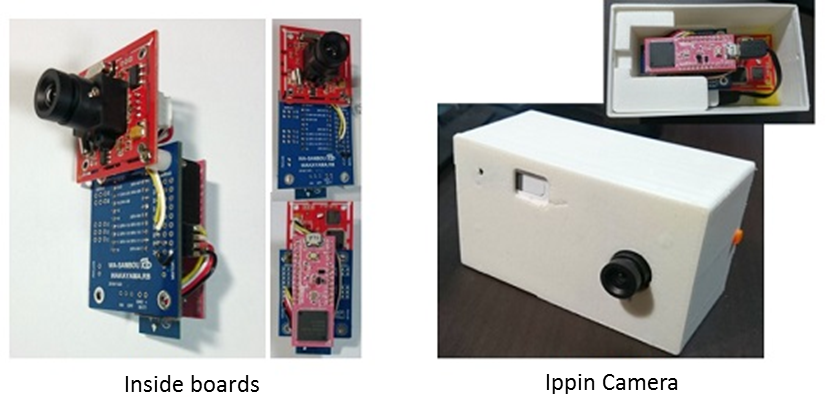

(1) Build the Ippin Camera

- We made the Ippin camera using GR-CITRUS + WA-MIKAN + camera module.

- We succeeded in converting the Ippin camera to WiFi AP, enabling operation of the system via a browser.

- We gave up transfering data captured by camera via WiFi since it takes a very long time.

- We installed the STL data generation function in the Ippin camera.

- However, since it takes time to generate the STL data with the Ippin camera, we made it possible to create STL data mainly using the PC.

(2) PC software development

- We developed software that creates stamp data from the STL formatted image data.

(3) Mold design

- Design the mold for a soy sauce plate and print the mold using a 3D printer

- Design a frame for the stamp and print the combined mold of the frame and the stamp with the 3D printer.

(4) Design production process and operation

- We established the production process for a floating image plate (refer to the YouTube video for actual production)

- We succeeded in manufacturing lots of plates with a single mold

- Plate production is completed by firing the plates in an oven

GR Design Contest 2017 Finalist